Despite all the news of re-openings, lifted restrictions, al fresco options dining, and a return to something more closely resembling “normal,” COVID-19 is still very much with us. And despite the defeatist/downplayed/nothing to see here stance embraced by the current presidential administration, the United States is still in the midst of an unprecedented public health crisis. In some states, both new reported cases and hospitalizations have now reached record highs.

This being said, the need for accessible, easy to fabricate, and quick-to-deploy testing facility solutions are still in great need, particularly in dense urban areas, at large institutions and workplaces, and in underserved communities where coronavirus testing might come as a luxury, not a basic necessity. In terms of testing availability, all bases need to and must be covered.

Major architecture firms including Perkins and Will, Grimshaw, and HOK have all responded to this ongoing need with mobile and/or modular COVID-19 testing labs—some of them employing creative means of adaptive reuse–that fill in the gaps left by static, hospital- or clinic-bound testing options that can adequately serve some but not necessarily all. Here’s a look at three of them, and we will add similar design solutions as we come across them.

From Perkins and Will with Schmidt Hammer Lassen Architects and Arup Group:

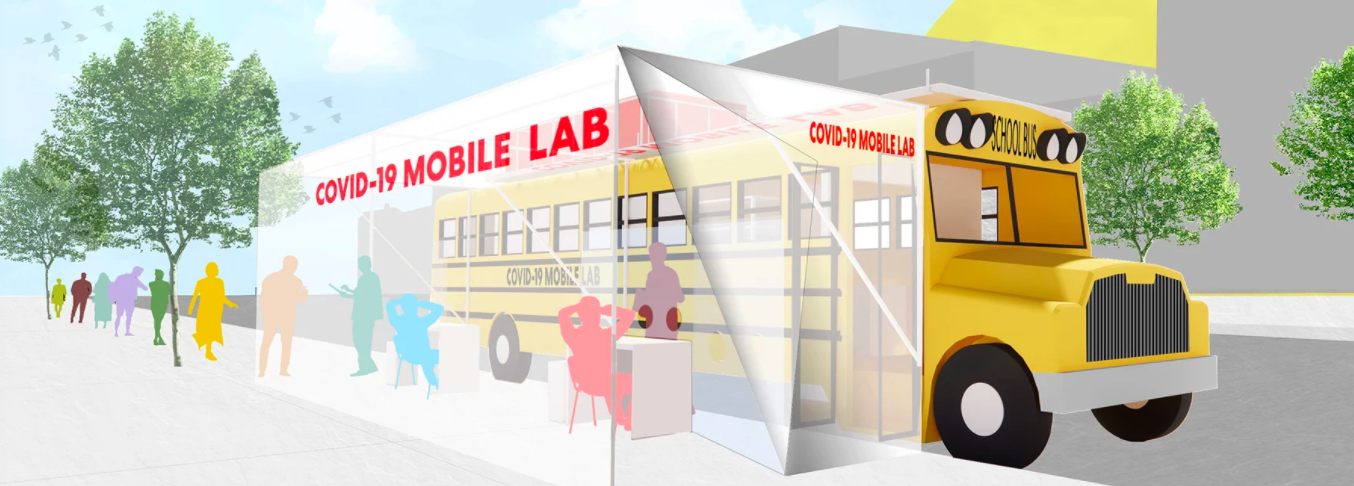

Mothballed school buses are no stranger to creative reuse, and that certainly applies to the COVID-19 era. With support from its Innovation Incubator program, members of Perkins and Will’s New York studio, working alongside its Danish studio Schmidt Hammer Lassen and Arup Group, have conceived a “scalable, quick, inexpensive, and easily replicated” mobile coronavirus testing lab concept geared specifically to be deployed in high-density and underserved neighborhoods that’s housed within the shell of a friendly and familiar sight: the standard yellow school bus.

“While no one is immune to the COVID-19 virus, testing and treatment is not a level playing field. It is the under-served communities, including lower-income and homeless populations, that need our urgent help at this time,” said Mariana Giraldo, architect and strategic planning specialist in Perkins and Will’s New York studio, in a press release. “We wanted to harness the expertise of our interdisciplinary team to help those in need during the crisis. We believe the mobile testing lab is a scalable and accessible solution to close the gap on testing in our home, New York City, and across the world.”

As explained by Perkins and Will, the design team set out to envision a mobile testing unit solution that met seven key parameters: equitability, mobility, accessibility, speed, flexibility, ease of implementation, and scalability. And retrofitted disused school buses checked all the boxes.

“Perkins and Will based the layout of the mobile testing lab concept around the newly-approved Abbott ID NOW COVID-19 test, enabling vulnerable populations and isolated groups to be tested and receive their results within minutes. Ideally, individuals would be referred to the mobile testing lab through doctors and appointments would be made through a mobile app, so that crowds could be controlled and social distancing rules adhered to. Of course, given the testing solution’s emphasis on equitability, smartphone access or a referral from a doctor is not a pre-requisite and everyone is welcome to sign-up.

Upon arrival, individuals are greeted by technicians behind a plexiglass shield underneath a canopy. Following a brief check-in process, the technician would take a sample using a swab from the individual’s nose and/or throat. Their samples would then be labeled or barcoded and brought into a lab environment on the bus via a pass-through box.

The labs would host two technicians who would run the samples collected through the ID NOW rapid testing instrument. Once results are received, they would be recorded and uploaded to the federal government’s official database. Tested samples and the expended test materials would then be placed in biohazard waste bags and discarded safely. For tested individuals with mobile app access, results would be sent through a phone notification. For those without, results could be relayed verbally.”

Perkins and Will is now looking for project partners to turn the concept, which also could be potentially used for antibody testing and for administering future vaccines to vulnerable populations, into a reality.

From HOK with Germfree:

Conceived in collaboration with the reassuringly named biosafety lab manufacturer Germfree Laboratories Inc., HOK’s rapidly deployable modular COVID-19 mobile testing lab concept is geared for testing for active/suspected infections at large institutions—college campuses, corporate office parks, large-scale manufacturing facilities, governmental compounds, and the like—where speed and volume are top concerns.

“We developed this solution to help our clients, many of whom have many employees or students that will require regular testing with immediate results,” said Tim O’Connell, director of Science + Technology for HOK. “We considered the architectural object as much as the operational efficiency of the lab, imbuing the modules with details that make them friendly and welcoming to the people who’ll use them and appealing additions to an office park, city or campus.”

“Comprised of two Germfree modules, the labs accommodate up to nine staff workers as well as one or two high-throughput diagnostic machines capable of testing 80 samples at a time, resulting in up to 1,120 tests per day. One module is dedicated to sample collection and the second to testing.

The modules feature rounded window frames and door openings, which contributes to a modern and inviting appearance. Considering the needs of those visiting the lab, HOK designed special ‘flaps’ that cover the various doors while the module is in transit and also open to create a ‘porch’ that provides protection from sun or rain. Patterned film covers some windows, providing privacy for visitors during sample collection and other procedures.

HOK’s design ensures the efficiency of each unit while putting science on display via views into the testing area. Exterior graphics can educate visitors about the testing process, provide information about the virus and the sponsoring institution.”

There are plans to deploy the units by mid-fall when students at colleges and universities will be (tentatively) returning to campus en mass. A smaller mobile testing solution that will provide same-day testing to smaller groups is also in the works.

From Grimshaw with SG Blocks and Osang Healthcare:

Prototype units of D-Tec, rapid COVID-19 testing facilities developed by Grimshaw in partnership with shipping container specialists SG Blocks and South Korean medical supply company Osang Healthcare, are due to be completed this month. The modular units, which take advantage of the versatility and availability of retired shipping containers, are easy to assemble and quick to both deploy and relocate.

The units are “designed to facilitate a safe screening protocol while serving the greatest number of patients possible,” explained Grimshaw in a press statement. “Medical staff are inside the facility, separated from patients who approach the exterior. Testing can be done without contact between staff and patient.”

Like with other shipping container-based solutions, there’s the potential to create multi-unit configurations that, in addition to testing services, would include on-site laboratories or even full-service medical clinics.

“Grimshaw recognizes the important role that a rapidly deployable solution has in opening up greater access to testing that people can trust and rely on,” said Grimshaw chairman Andrew Whalley. “We have always aimed to deliver progressive architecture that strives for a better future, and we believe this suite of highly adaptable, efficient building solutions developed by our Industrial Design team will provide greater opportunities for the critical role testing, and people’s trust in testing sites, will play as we move forward.”