Researchers at Rice University have developed a technique that makes 3D-printed common materials diamond-hard. Inspired by the theoretical form of tubulanes—a carbon nanotube structure that scientists predicted in the 1990s would have tremendous strength but have been unable to produce—the researchers scaled the structures up and found that these larger-scale imitators still maintained many of the theoretical nanotubes’ powerful properties. The team, headed up by Seyed Mohammad Sajadi working at the lab of Pulickel Ajayan, recently reported their results in the journal Small.

Tubulanes were conceived of by chemist Ray Baughman of the University of Texas at Dallas and physicist Douglas Galvão of the State University of Campinas, Brazil back in 1993 (both authors are named as co-authors of the recent paper, “3D Printed Tubulanes as Lightweight Hypervelocity Impact Resistant Structures”). Back in 2017, the researchers at Rice also demonstrated that another theoretical nanostructure, schwarzites, could similarly be approximated at a larger scale with traditional materials. While it remains outside the scope of current technology to produce the theoretical tubulanes, the creation of a scaled-up version of these interlocking curvacious forms promises many advantages over traditional structures.

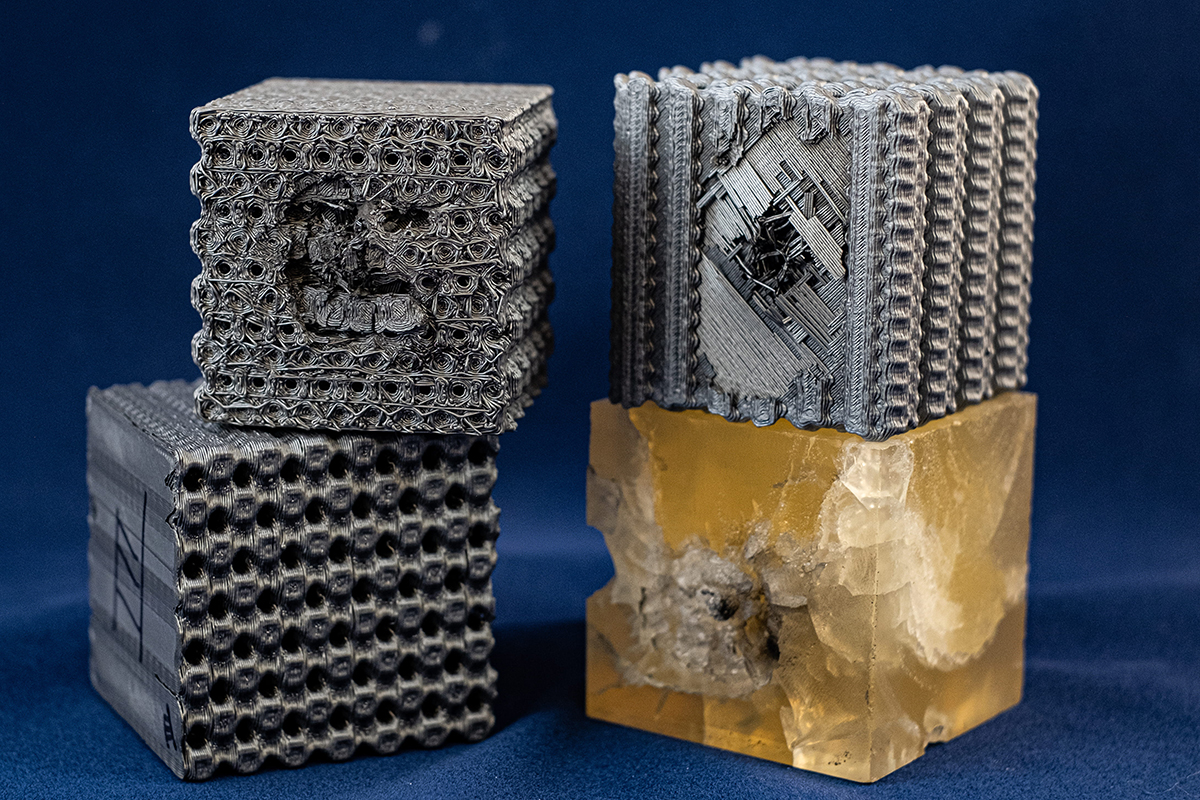

The scientists first ran computer simulations of various blocks made of tubulane-inspired forms, before 3D printing polymer versions. They then put the hole-filled blocks to the test the best way they could: by shooting them. Unlike solid blocks of the same material that shatter, these blocks barely dented, proving themselves ten times more effective at stopping a bullet than the solid counterparts. Under crush tests, the sample structures similarly folded in slowly, rather than shattering or losing all structural integrity.

But what does this mean for architecture? The team at Rice envisions a future where ceramic, concrete, steel, and other common building materials could be printed in porous tubular approximations. Limited only by the size of the printer, these structures could someday form the basis of ultra-strong building materials that are more durable and react more safely to stress, all while being lighter and, if left uncovered, having a unique, knit-like aesthetic.