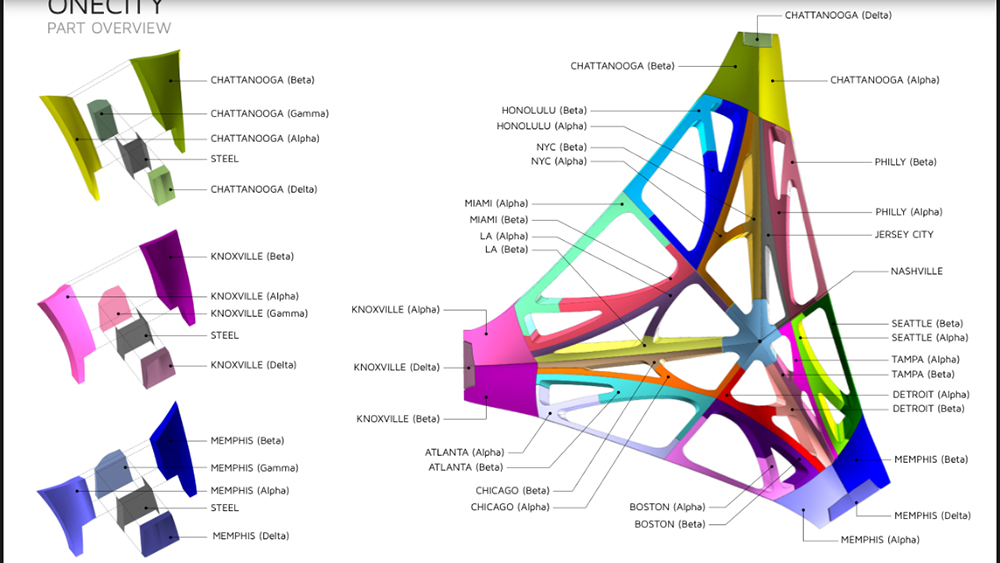

On July 18th, Chattanooga-based architectural fabricator Branch Technology unveiled the world’s largest 3D-printed structure, a bandshell pavilion measuring 20-feet-tall and 42-feet-wide. The pavilion was first announced in Cambridge, Massachusetts during MIT’s 2018 International Association for Shell and Spatial Structures. The structure is located in Nashville’s emerging smart-city neighborhood, OneC1TY.

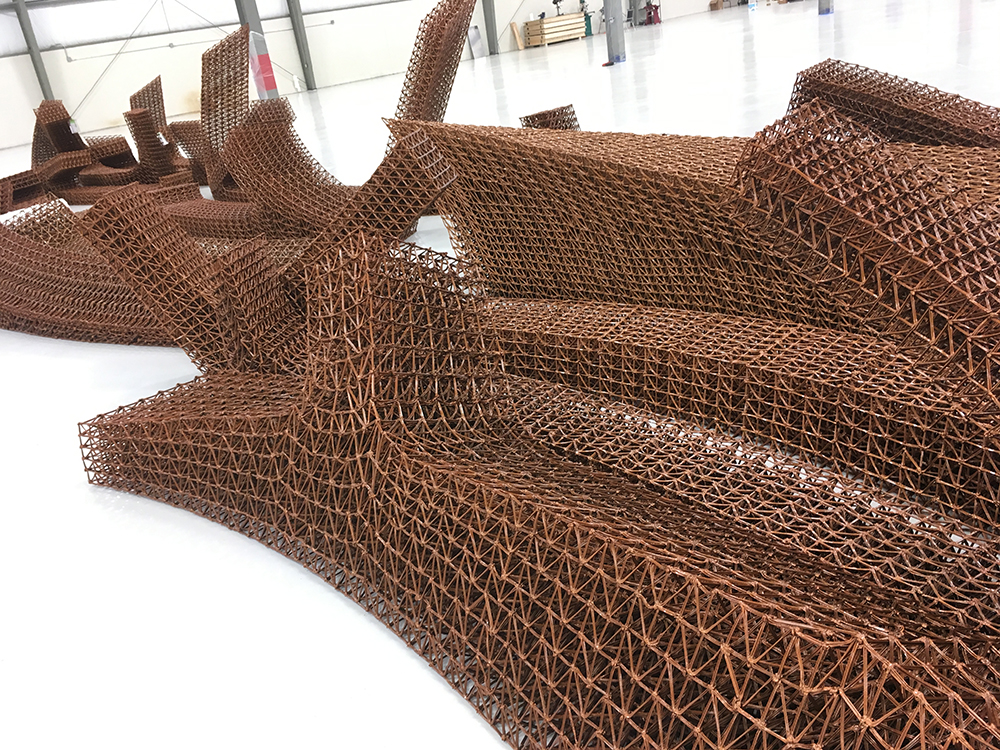

Reported by Architect Magazine, the carbon fiber-reinforced Acrylonitrile Butadiene Styrene sculpture was designed in collaboration with Thornton Tomasetti’s CORE Studio. Using Branch’s Cellular Fabrication, or C-Fab, technology, the structure was printed as 36 separate sections over the course of 10 weeks. Then, the sections were transported and assembled on site.

The pavilion weighs approximately 3,200 pounds, with the largest section reaching just under 300 pounds. To comply with Nashville’s normal building code, Branch Technology’s design possesses a structural strength capable of withstanding up to 12 inches of snow and a 90mph wind load.

In a statement, Branch Technology describes the cellular matrices produced by C-Fab as allowing “for efficient builds and endless geometric form.” In terms of architectural application, “the matrix acts as a formwork or scaffold to accept traditional building materials.”

In a 2016 collaboration with SHoP Architects for Design Miami, Branch Technology created the Flotsam & Jetsam pavilion which was similarly composed of an undulating network of cellular matrices.