In Aarhus, Denmark’s second largest city, a consortium of architects, engineers, and manufacturers are advancing the capabilities of concrete construction formwork and advanced design. This effort culminated in a recently unveiled 19-ton prototype dubbed Experiment R.

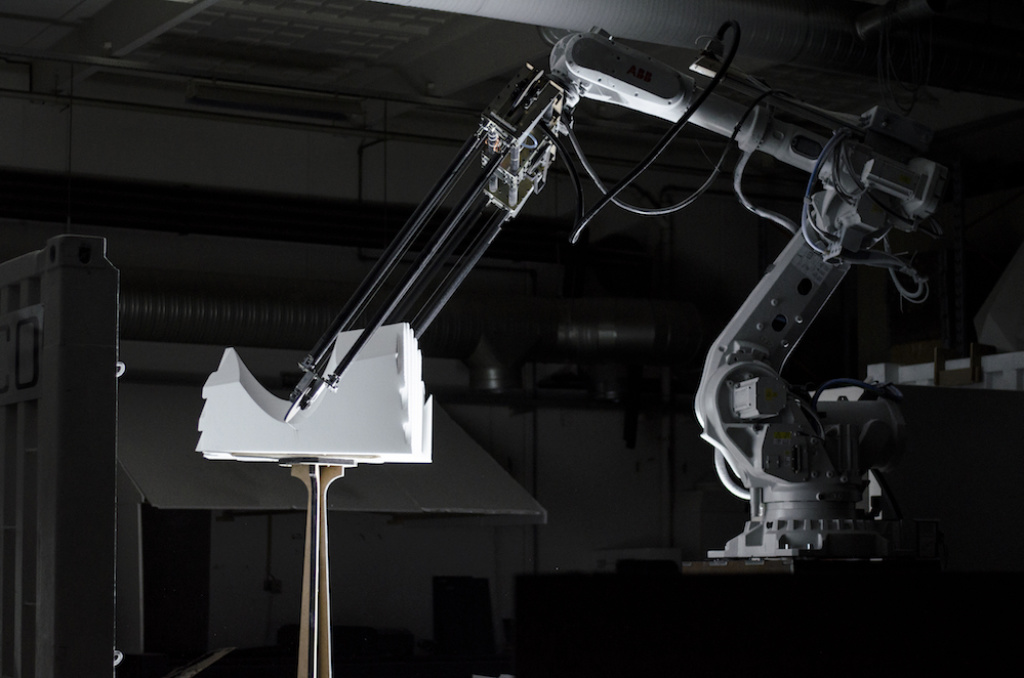

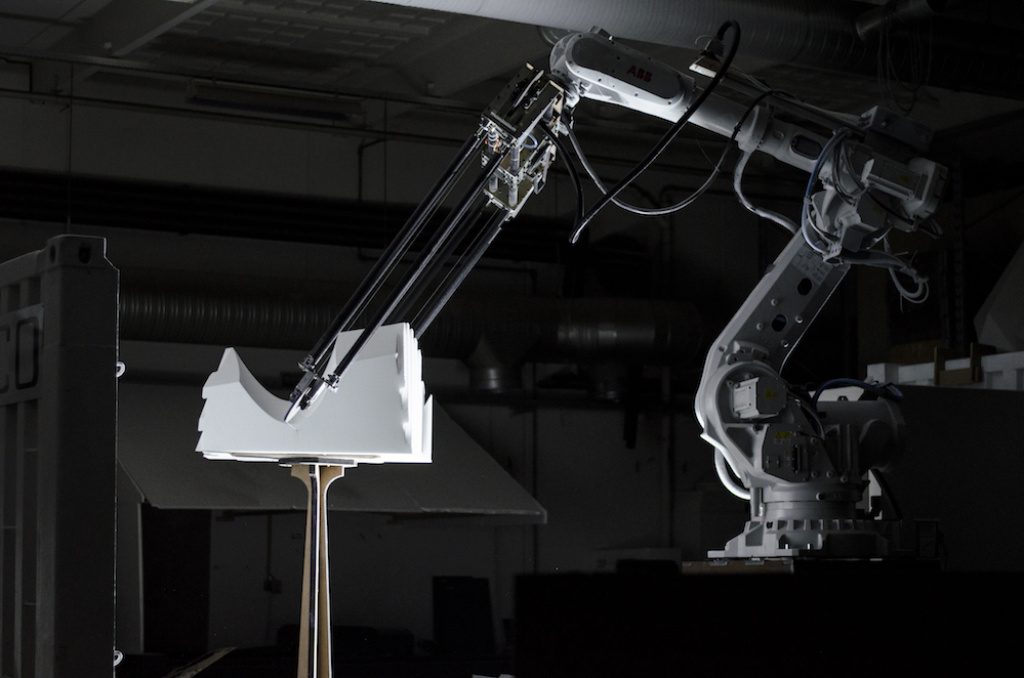

The project, led by the Aarhus School of Architecture, Odico Formwork Robotics, Aarhus Tech, concrete manufacturer Hi-Con, and Søren Jensen Consulting Engineers, tackles the waste associated with concrete formwork through the use of a novel robotic fabrication method.

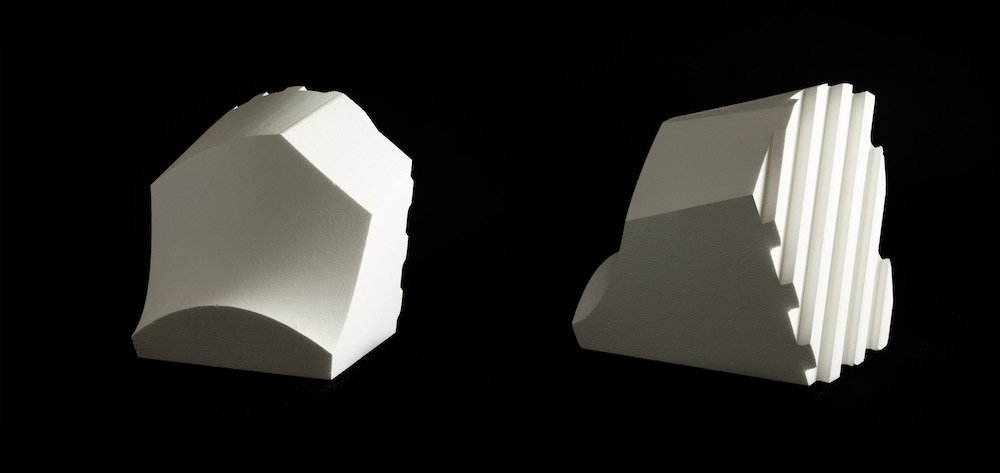

How does this new method work and why is it potentially so disruptive? According to the Aarhus School of Architecture, formwork is easily the most expensive aspect of concrete construction, making up to three-quarters of the total cost of a concrete project. Significantly reducing waste associated with the formwork process and the molds themselves boosts environmental performance and the economic feasibility of complex concrete geometries.

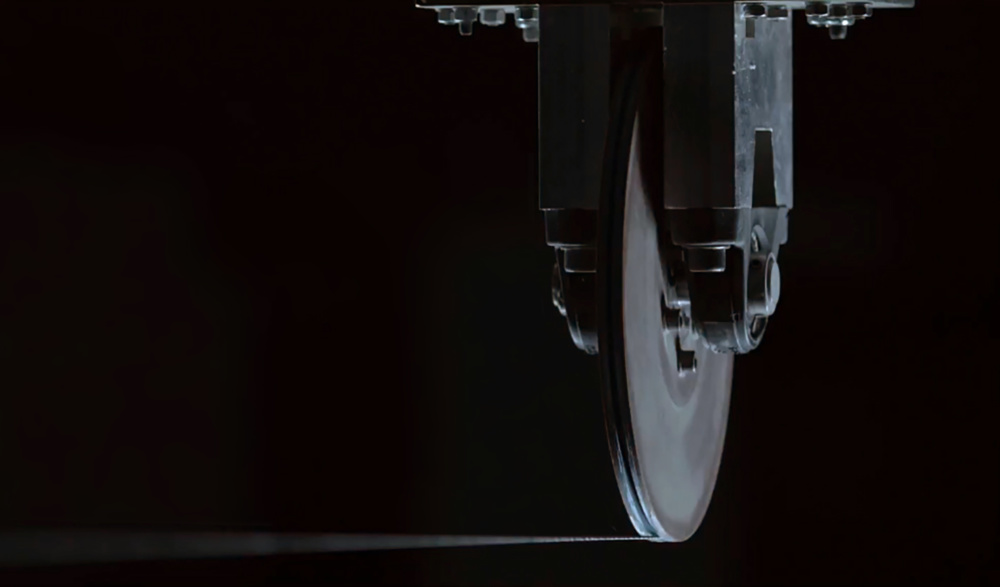

The project’s new apparatus consists of a heated and electrically powered wire rotating at a speed of approximately 160 feet per second around a carbon fiber frame. This device is mounted atop a robotic arm, which can shape complex detailing. While a polystyrene mold was used for the formwork of Experiment R, the mechanism has the capacity to cut through harder materials such as stone and timber.

Conventional methods of formwork fabrication are significantly more laborious—a typical CNC milling machine is able to process an 11-square-foot surface in approximately three to five hours. In an action that Asbjørn Søndergaard, chief technology officer of Odico Formwork Robotics, refers to as “detailing the whole formwork in one sweep,” the new technology is able to process that same surface area in 15 seconds. Strikingly, this timescale is applicable to both straightforward and advanced design formwork.

The 19-ton Experiment B prototype, installed adjacent to Aarhus’s Marselisborg Lystbådehavn in July 2018, is an extreme example of what can be achieved with this new method, displaying future possibilities of construction. According to Søndergaard, it is the hope of the consortium that the highly optimized concrete formwork is translatable and ultimately adopted for everyday projects such as minor infrastructural works and standard residential or commercial development.