What if we could “breed” buildings to be more efficient? That’s the provocation by artist, designer, and programmer Joel Simon, who was inspired by the potentials of 3D printing and other emergent digital manufacturing technologies, as well as his background in computer science and biology, to test a system of automated planning.

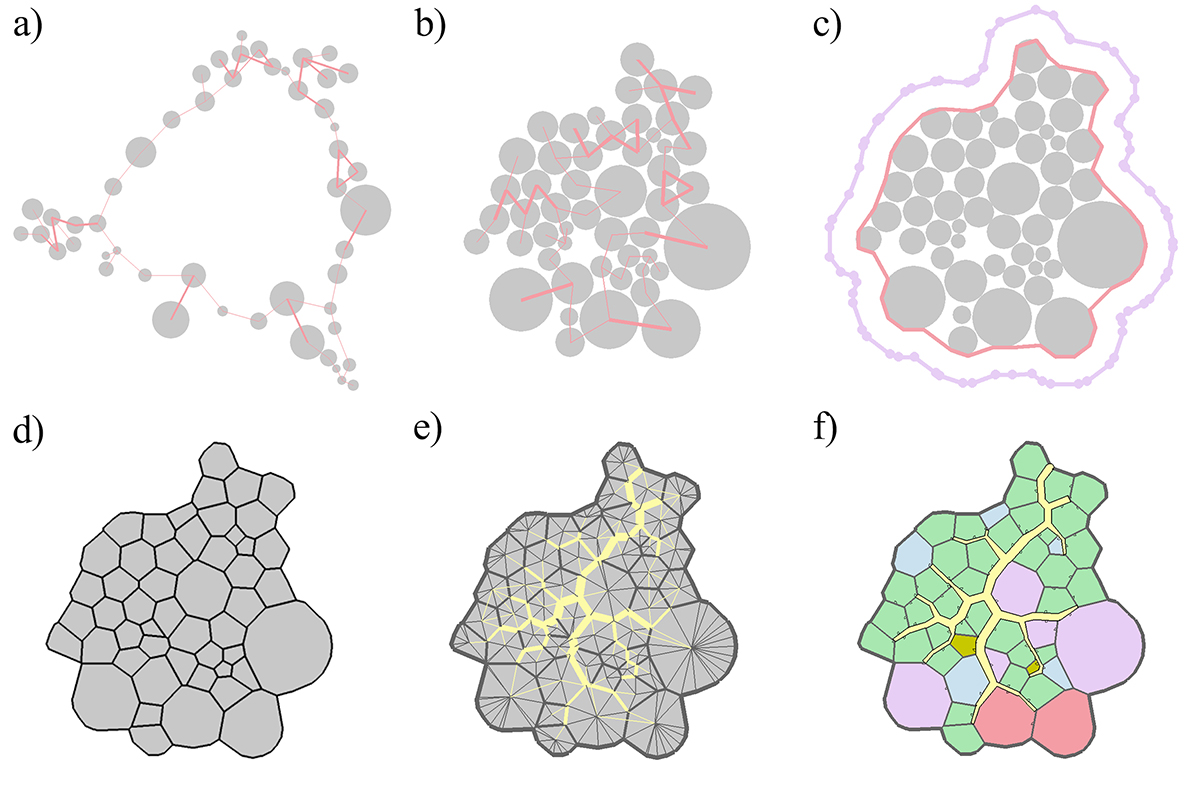

With a series of algorithms of two types—“graph-contraction and ant-colony pathing”—Simon is able to “evolve” optimized floor plans based off different constraints, using a genetic method derived from existing neural network techniques. The results are, according to a white paper he put out, “biological in appearance, intriguing in character, and wildly irrational in practice.”

The example he gives is based off an elementary school in Maine. Most schools are long corridors with classrooms coming off the sides, a highly linear design. By attempting to set different parameters, like minimizing traffic flow and material usage, or making the building easier to exit in the event of an emergency, the algorithms output different floor plans, developed on a genetic logic. But this optimization is done “without regard for convention [or] constructability,” and adding other characteristics, like maximizing windows for classrooms, led to complicated designs with numerous interior courtyards. For projects like schools, he suggests, class schedules and school layouts could be evolved side-by-side, creating a building optimized around traffic flow.

While perhaps currently impractical (there’s no getting rid of architects—or rectangles— yet!), Simon hopes that the project will push people to think about how building with emergent technologies—like on-site 3D printing, CNC, self-assembling structures, and robotic construction—can be integrated within the design process. These technologies have promises for new forms that are hard to design for, he believes, and potentials that can’t be realized through existing design methods. As he told Dezeen: “Most current tools and thinking are stuck in a very two-dimensional world…[but,] designing arbitrary 3D forms optimized for multiple objectives—material usage, energy efficiency, acoustics—is simply past human cognitive ability.”