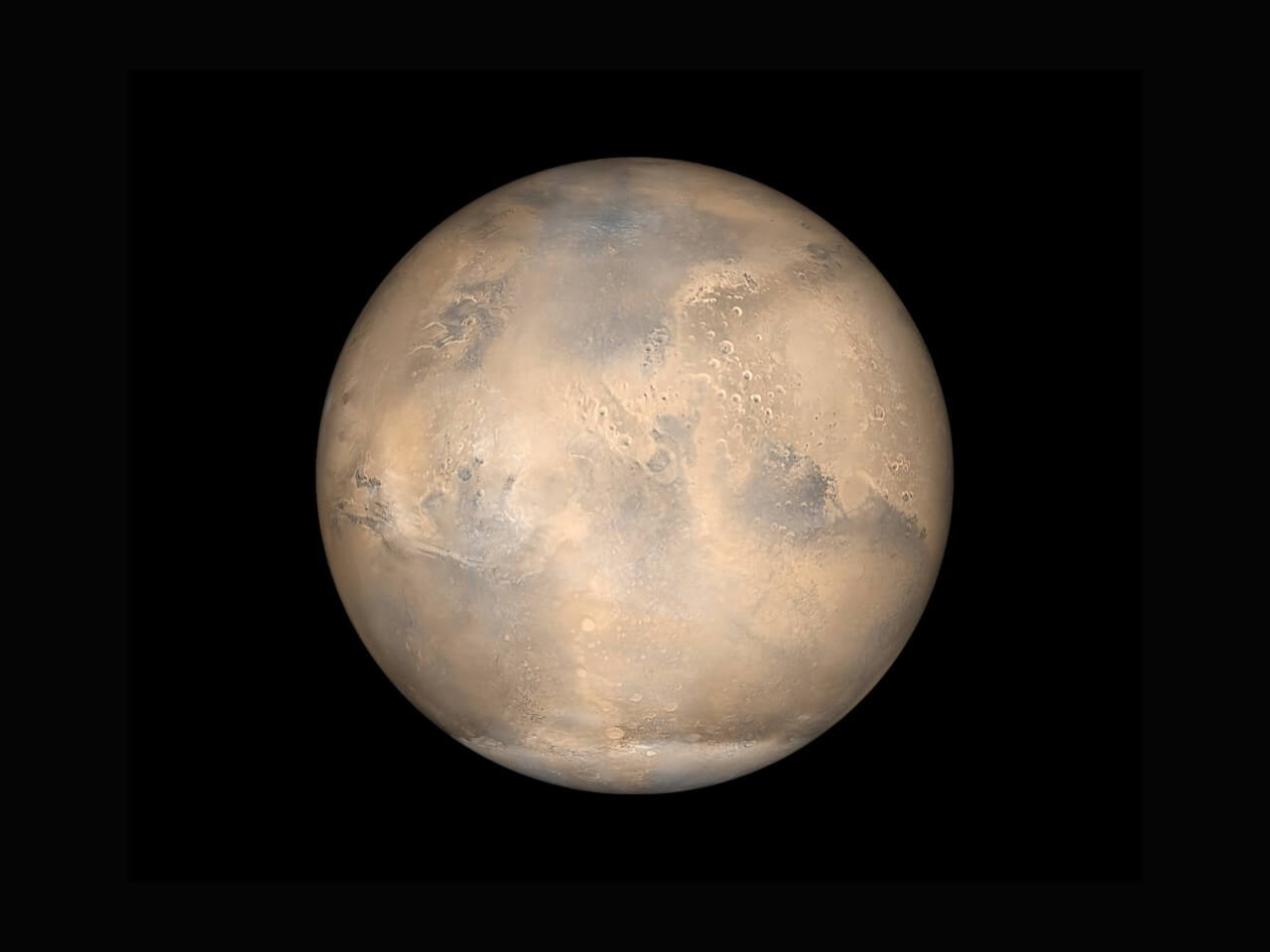

NASA, Bjarke Ingels Group (BIG), SEarch+ and Apis Cor, and a host of other governmental bodies and design firms have made the news of late for proposals to 3D print Martian habitats from locally sourced regolith in-situ. These sorts of schemes all focus on easy-to-transport methods of construction with materials already on the Red Planet to build out vital infrastructure and protect astronauts from radiation. But what if there was a source of building materials that space agencies were overlooking? One that’s much more… sustainable than traditional cement or brick?

According to a new study released in Materials Today Bio on September 10, human blood used as a binder with Martian soil forms a biocomposite with a compressive strength equal to terrestrial concrete—and urea extracted from urine, tears, and sweat created a biocomposite material with 300 percent more compressive strength. Typical Earth-bound concrete can withstand approximately 20 to 32 megapascals of pressure (MPa), whereas the “blood concrete” produced by researchers reached compressive strengths of 25 MPa. The urea mixture withstood pressures of up to 39.7 MPa, and both composites were suitable for 3D printing.

The research team compared the efficacy of biocomposite concrete with several other alternatives, such as spider silk-bonded concrete (finding that spiders are too difficult to farm for their webbing) and melted and cast regolith, which, while orders of magnitude stronger at 550 MPa, has infeasible energy requirements to produce. Bovine-based biocomposites were considered as well but the obvious difficulties and expenses of transporting and caring for cows ruled that option out as well, though the byproducts like milk and leather possess their own value.

The key to the material’s strength is human serum albumin (HSA), a protein found in blood plasma. When the protein denatures (or curdles), it binds with the regolith and acts as a matrix for the material. Because urea denatures proteins, adding it to the mixture breaks the HSA down faster and further strengthens the resultant “concrete.”

Mixing blood, sweat, and tears into building materials isn’t a new or novel idea; Romans mixed animal blood into their concrete to create small air pockets that allowed structures to freeze and thaw safely without incurring damage, and bone china, as the name suggests, uses bone ash from calcined cattle bones to create lightweight, high-strength porcelain. Of course, the issue in taking these materials from humans in the quantities required could create a psychological hurdle, a factor researchers noted in the negatives column for HSA biocomposites. The report estimates that colonists would need to donate their blood once every two weeks to create the necessary amount of HSA and that six colonists donating over a two-year mission span could create up to 1,100 pounds of high-strength biocomposite.

Of course, all of this research was done on Martian regolith analogs as the team lacked samples of firsthand material. It’s entirely possible that this novel approach won’t actually work on Mars (or the Moon, as the team also anticipated it would apply to lunar regolith too), but only real-world experimentation will tell.