Amsterdam-based firm MX3D has completed the full span of its 3-D-printed stainless steel bridge, designed by Joris Laarman Lab, a multidisciplinary team located in the Netherlands. The bridge will cross one of the city’s oldest canals, the Oudezijds Achterburgwal, and is approximately forty feet in length and over twenty feet wide.

Often using digital fabrication and 3D printing, the Joris Laarman Lab has over seventy projects featured in thirty-seven museums across ten countries including MoMa and the Centre Pompidou.

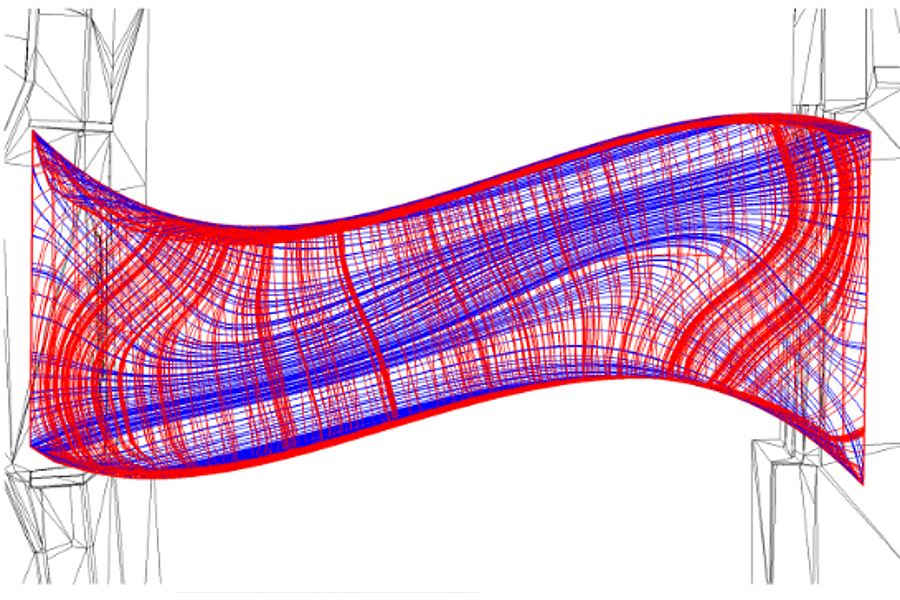

Utilizing software specifically designed by MX3D, the bridge was constructed by four multi-axis industrial robots. In total, it took six months for the robots to print the nearly five-ton 3-D printed bridge. While the construction process did require human input, the overall project tested the feasibility of robots printing bridges without human intervention and ultimately validated such an approach for future projects.

In a collaboration with The Alan Turing Institute, the long-term management of the bridge will rely on the use of a smart sensor network that is capable of testing structural measurements, such as vibration, strain and displacement, along with air quality and temperature. Through data collection, engineers will create a ‘digital twin’ of the new bridge, a constantly adapting computer model that reflects the structures altering state. This model allows for the effective repair of the bridge and provides insights and guidance for future construction.

The bridge will be subject to further structural testing as well as decking and coating. The expected installation date is October 2019.