Sidewalk Labs, the architecture and urbanism spinoff of Google parent company Alphabet, has detailed a new model for designing tall timber towers on their Medium page. The “digital proof-of-concept,” designed in Revit and hosted in BIM 360, is called PMX (proto-model X), and is intended to show how a modular 35-story tower could be designed and built effectively and efficiently using almost exclusively timber.

The Sidewalk Labs team went through eight design steps: Addressing site (the decision was to make the design site-agnostic), massing, structure, program, MEP, a passive house–like envelope, Ontario code compliance (likely to speed the process along when implementation in Quayside, Toronto), and ease of manufacture.

The structure itself is perhaps what is most interesting about PMX—the design is pretty basic—which also is directly tied to its ability to be modularly fabricated, as well as allowing for the maximum amount of space for tenants.

With timber being much lighter than concrete, winds became an issue during testing. The researchers found that because the building was as much as 2.5 times lighter as a traditional structure, lateral forces acted on it more like a typical 40- or 50-story building. However, Sidewalks Lab wanted to avoid a hybrid solution that added steel or concrete.

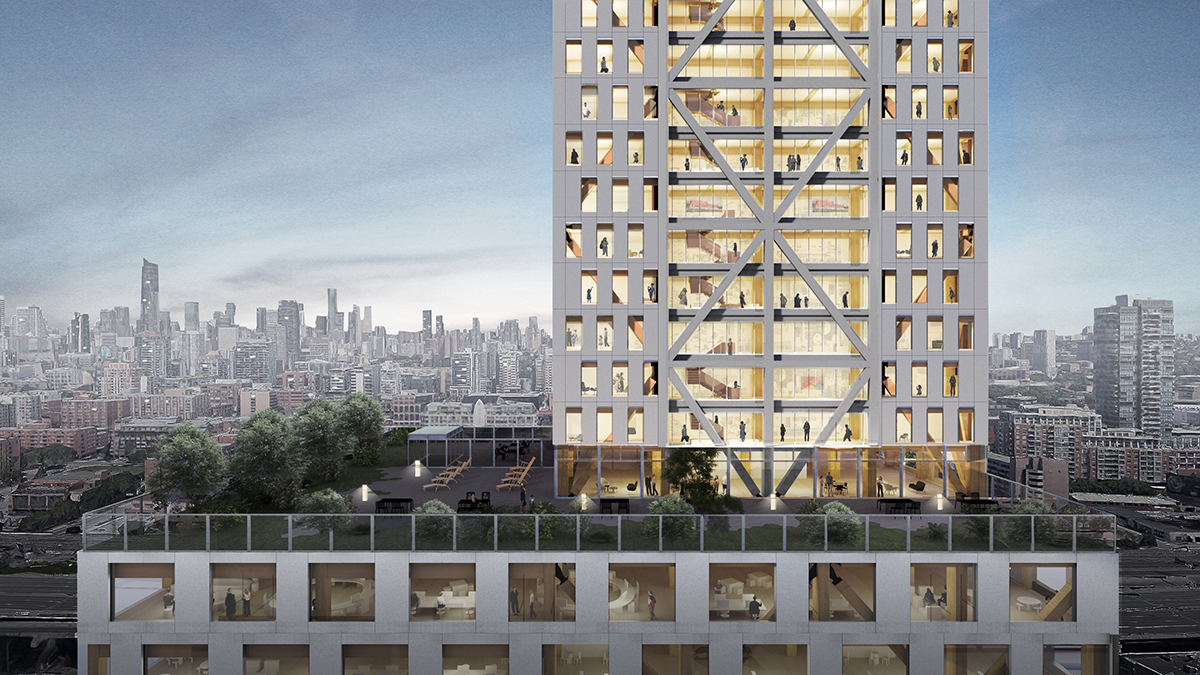

A timber structural core, they reported, would have necessitated walls that were five feet thick. Since this was unfeasible given the difficulty to manufacture and the resultant loss of floor space, Sidewalk Labs instead chose to use a cross-brace frame exoskeleton, like those found on many supertall towers. Since the exoskeleton still left the building fairly susceptible to large swaying motions, the team opted to add a 70-ton steel tuned mass damper at the penthouse level.

To create a design that was easy and affordable to manufacture offsite with CNC machines, the Sidewalk Labs team created an interlocking kit of parts, including a “floor cassette” which used wood panels, layers of acoustic padding and insulation, and space for plumbing, electrical, and mechanical infrastructure. To make the cassettes work, Sidewalk Labs designed a standardized grid for columns to plug into, which kept everything standardized for easy construction where sequence order becomes more or less irrelevant. The cassettes also feature stone wool, a fibrous structure of minerals, in place of concrete, and can be built in 25 steps.

The envelope is also modular, and the standardized metal panel has 40 percent window coverage and space for a balcony can be slotted into. However, to offer more aesthetic possibilities, each building could also be “skinned” to produce various effects, some of which have been speculatively designed by Gensler, such as a faceted skin of waving forms.

What this means for Sidewalk Labs’ contentious Toronto waterfront project, which past renderings included designs from Snøhetta and Heatherwick Studios, is not certain. It may mean revisions to the proposed designs of the taller towers, of which renders were first released back in February 2019. Cara Eckholm, associate director of development at Sidewalk Labs, when asked about the differences in the visuals commented: “The renderings in the MIDP were illustrative, and do not represent final project design. Similarly, the images posted in the PMX model blog post are used to demonstrate potential variations using different facade materials.” Regardless of whether the research is implemented, the model demonstrates a future for building up with timber, providing more sustainable options than the common carbon-intensive glass and concrete construction.

For more on the latest in AEC technology and for information about the upcoming TECH+ conference, visit https://techplusexpo.com/events/la/