Just weeks after it announced a partnership with the Virginia Center for Housing Research at Virginia Tech to design, build, and study America’s first 3D-printed, private-public partnership grant-funded single-family home in Richmond, Alquist has revealed another unprecedented project underway in Williamsburg, Virginia. This time, it’s the East Coast’s first 3D-printed Habitat for Humanity dwelling. The project, spearheaded by additive construction company Alquist with Habitat for

Additive construction company Alquist and the Virginia Center for Housing Research (VCHR) at Virginia Tech have partnered to design, build, and study a 3D-printed single-family home that’s the first of its kind in the United States: funded by a private-public partnership grant. Work on the three-bedroom, 1,550-square-foot home broke ground earlier this week at 217 Carnation Street in Richmond’s Midlothian neighborhood.

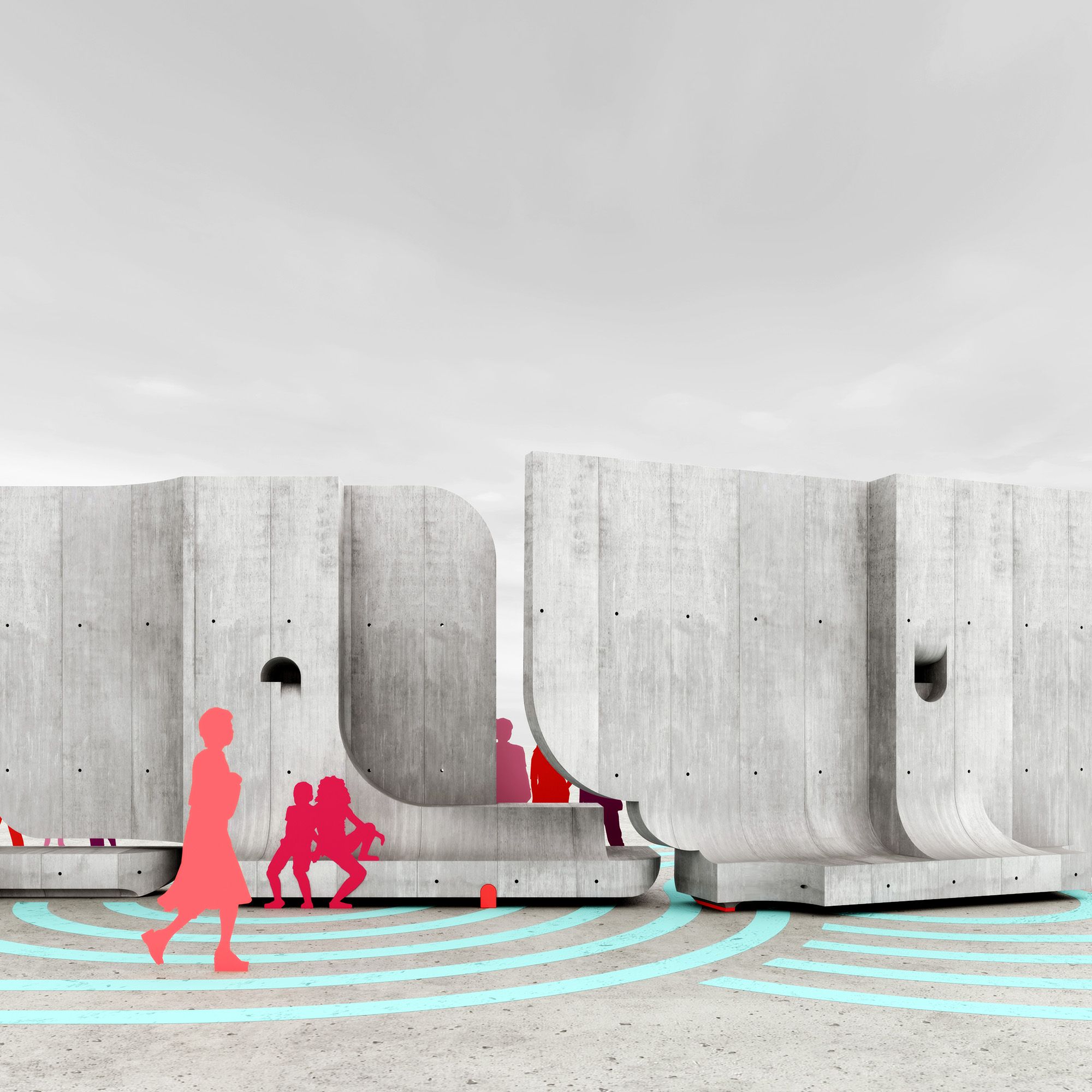

AquíAquí, the latest collaboration between Cambridge’s Matter Design and multinational CEMEX Global R&D (a frequent partner in realizing the firm’s monumental and kinetic concrete designs) is a speculative community gathering space along the El Paso/Ciudad Juárez border intending to bridge both cities. In AquíAquí (Here Here), Matter Design has envisioned an outdoor “community center” for Parque

Cambridge, Massachusetts–based Matter Design has unveiled its latest concrete collaboration, an outdoor “play-lab” at the Grayson School in Radnor, Pennsylvania, that balances hulking cast concrete forms with mix-and-match freestyle play. Explorations into play have always found their way into Matter Design’s projects, whether it be in the rollicking performances of Janus, or the rollable Walking

The Cambridge, Massachusetts–based practice Matter Design, directed by Brandon Clifford and partners Jo Lobdell and Wes McGee, is rethinking what performance and sustainability mean in architecture. “In the past few years the conversations we were having were falling outside of the conventional discipline of architecture,” Clifford said. “If you start to talk about sustainable building

Mexico City-based architect Gerardo Broissin has created a jigsaw puzzle-like concrete structure for the courtyard of the celebrated Museo Tamayo. Built for Design Week Mexico this fall, the pavilion, known as Egaligilo (Esperanto for equalizer), forms its own porous microclimate full of ferns and shrubs. In order for the pavilion to successfully keep the plants healthy,

The Architect’s Newspaper has granted its 2019 Best in Design Awards to a number of standout projects, with the TWA Hotel refresh coming out on top as the Building of the Year. AN also recognized the best uses of innovative materials, digital fabrication, and other tech-forward AEC innovations this past year. In Research, LAMAS’s Delirious

Construction remains one of the most carbon-intensive industries, with materials often contributing significantly to the final project’s total pollution (concrete production, for example, is responsible for 8% of global carbon emissions). A report from the Carbon Leadership Forum, a network of academics and industry professionals hosted at the University of Washington to focus on reducing

While refugee camps are generally designed to be temporary, they often end up staying up for many years and become full, functioning cities in their own right, housing generations of people—Dheisheh camp, in Palestine, for example has been continuously occupied since 1949. However, because the materials they are built with—often just tents or tarps over

For the Chicago Architecture Biennial opening on September 19, SOM debuted a concrete pavilion called Stereoform Slab to showcase the latest in material and manufacturing technology. As much as 60 percent of a building’s carbon footprint can result from the creation of concrete slabs, according to SOM. By developing new fabrication methods and integrating robotic

Can you build with concrete in space? That is the question NASA and Pennsylvania State University researchers have been trying to get the answer to in their Microgravity Investigation of Cement Solidification (MICS) study. If humanity has any future on the moon or Mars, we’ll need shelter—not from rain or snow, but cosmic radiation and

For the Origen Festival in Riom, Switzerland students in the Masters of Advanced Studies in Architecture and Digital Fabrication program at ETH Zurich, guided by researcher Ana Anton, 3D printed nine unique, computationally-designed columns with a new layered extrusion printing process developed at the university over the past year and a half. ETH students and

Exhibit Columbus, the annual celebration of mid-century and contemporary design in Columbus, Indiana, will be showing off new possibilities of materials that unify support and envelope. This August, two of the festival’s six University Design Research Fellows will present this work as part of a brand new fellowship program. Marshall Prado, a professor at the

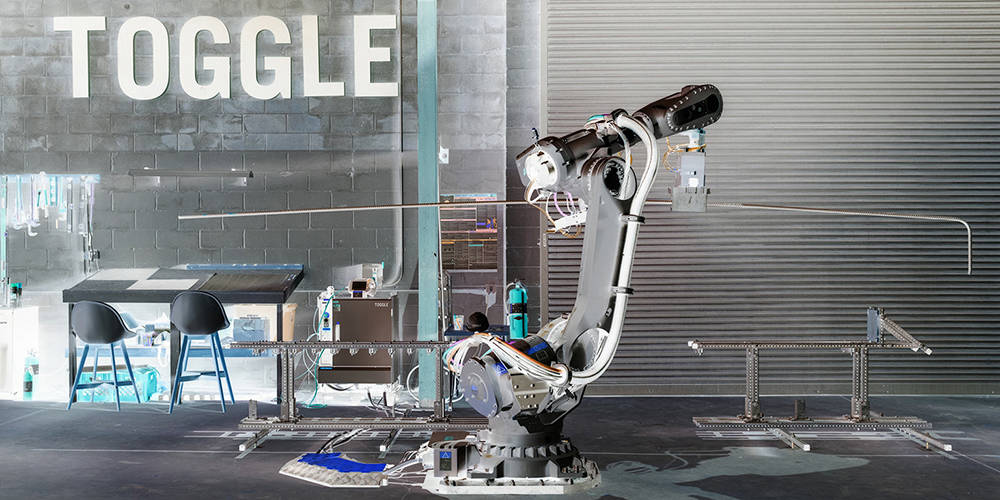

Two Brooklyn-based construction entrepreneurs began their business with a simple observation: steel rebar, used in concrete construction throughout the world, isn’t always easy to work with. Ian Cohen and Daniel Blank noticed this when they were watching wind turbines being erected. “Watching the process of people manually moving these huge, heavy objects looked dangerous and

“What if you could download and print a house for half the cost?” reads the lede for the Vulcan II, a 3D printer with a name suited for sci-fi space exploration, on the website of Austin-based company ICON. Now the company has put this claim to the test, building what it says is the first

ETH Zürich’s high-tech showhome opened its doors this past week. The three-story DFAB HOUSE has been built on the NEST modular building platform, an Empa– and Eawag–led site of cutting-edge research and experimentation in architecture, engineering, and construction located in Dübendorf, Switzerland. The 2,150-square-foot house, a collaboration with university researchers and industry leaders, is designed

Global construction continues to steam ahead, even while seemingly mundane building materials (like sand) become rarer and more precious, and construction industry’s carbon dioxide emissions contribute to global climate change. The building industry seems to be demanding new solutions, but scalable alternatives remain scarce. Enter the Block Research Group at ETH Zurich. The group, which is

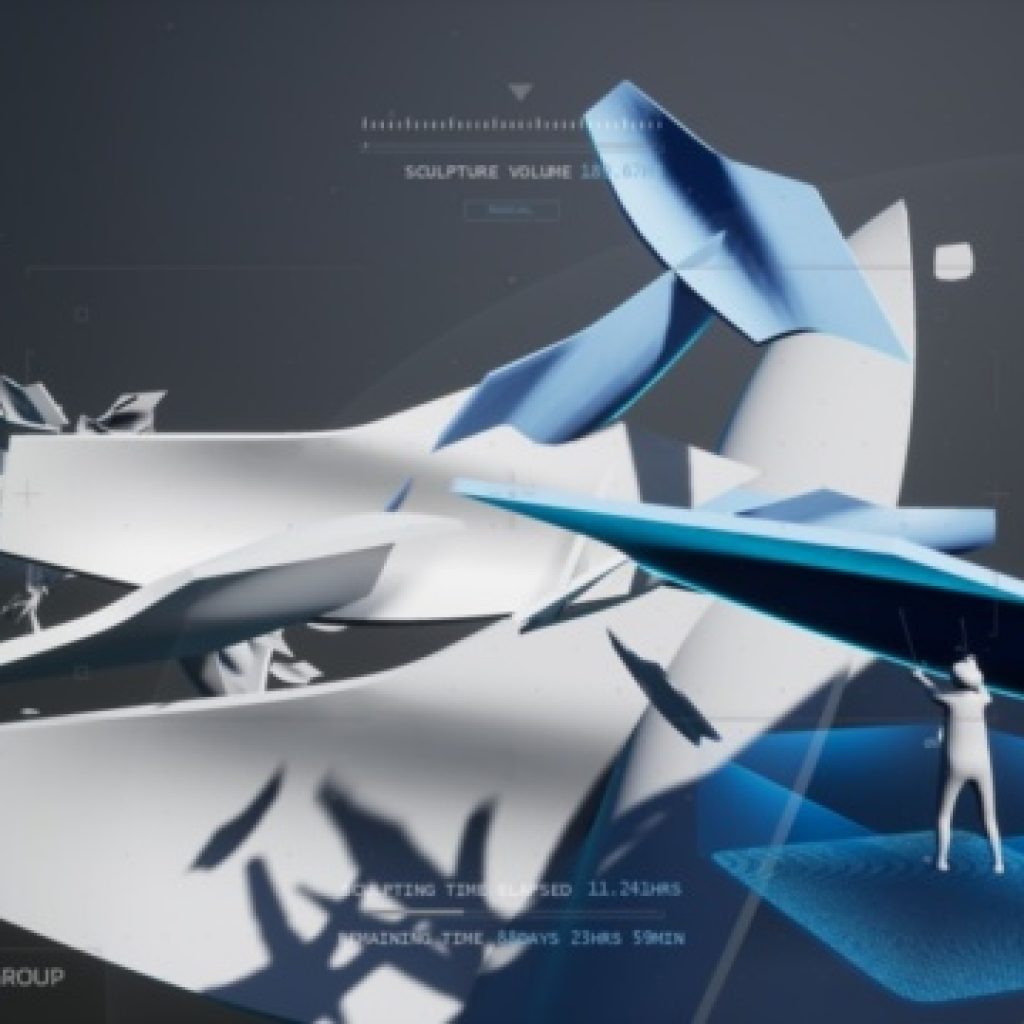

Virtual reality is often an individual experience, with one user shaping and traversing a preprogrammed digital realm. But what if complete strangers could gather together within the virtual realm to construct an architectural edifice? Project Correl is an experiment by the Zaha Hadid Virtual Reality Group(ZHVR) in what it describes as “multi-presence virtual reality,” where users can

Since the problem was originally identified in 2016, San Francisco’s Millennium Tower has been slowly but surely sinking and tilting westward towards the adjacent Mission Street. While Handel Architects, DeSimone Consulting Engineers, and the developer Millennium Partners contend that the execution and design of the project were sound, with the current structural issues stemming from the construction of the similarly defective Transbay

Concrete is a ubiquitous building material, applied to the bulk of contemporary construction projects. While the sedimentary aggregate is commonly used due to its impressive compressive strength, it remains a brittle material subject to damage or failure during extreme environmental events such as earthquakes. In response to this inherent weakness, a team of researchers based out

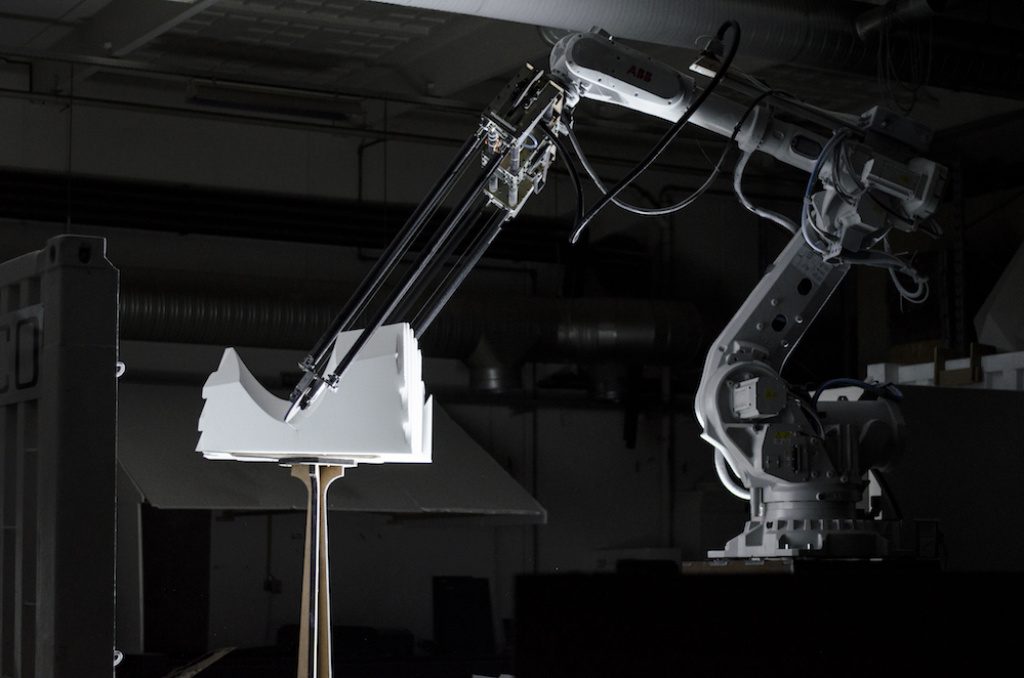

In Aarhus, Denmark’s second largest city, a consortium of architects, engineers, and manufacturers are advancing the capabilities of concrete construction formwork and advanced design. This effort culminated in a recently unveiled 19-ton prototype dubbed Experiment R. The project, led by the Aarhus School of Architecture, Odico Formwork Robotics, Aarhus Tech, concrete manufacturer Hi-Con, and Søren Jensen Consulting Engineers, tackles the waste associated with

Over the last decade, the renewable energy industry has boomed due to the proliferation of new technology that is reducing the cost of construction and long-term operability. However, one critical problem still remains: storing renewable energy during lulls in wind speed or sun exposure is often prohibitively expensive. In response to this issue, Energy Vault, a subsidiary of California’s IdeaLab,

A research team within the U.S. Army Corps of Engineers recently 3D-printed full-scale concrete walls in an effort to create quick-to-assemble barracks for field housing, according to Engineering News Record. The project, named Automated Construction of Expeditionary Structures (ACES), aims to engineer structurally efficient and safe concrete barracks with precast roofs and 3D printed walls. In their latest tests, they were able

A research team led by Jamin Dillenburger, an assistant professor at ETH Zurich, has recently produced and installed a concrete ceiling shaped by 3D-printed sand formwork. Dubbed the “Smart Slab,” the 1000 square-foot ceiling is significantly lighter and thinner than comparable concrete ceilings. According to ETH Zurich, Dillenburger’s research group “developed a new software to fabricate the formwork elements,